Ms. Kassie

Leave a message

Compact Cladding System Site Case

CC System Main Functions And Parameters

No | Configuration information | Specifications |

1 | Hot-Wire TIG welding Power System(Austrian Fronius) | Main power supply: TransTig 5000 Job G/F Hot wire power supply: TransTig 2200 Job G/F |

Welding method & welding current | Pulse TIG Peak current: 100-500A Base current: 100-300A | |

2 | Mechanical part | Cross manipulator, 5 Ton turntable, One medium-sized welding gun has an effective depth of 1m, equipped with an additional extension gun head. The minimum inner diameter after welding is 35mm, can weld 2-inch valve body cavities. |

Equipment effective stroke | X axis:1450mm Z axis:1900mm | |

3 | Control system | Mitsubishi QR controller |

No | Overview of equipment capabilities and functions | |

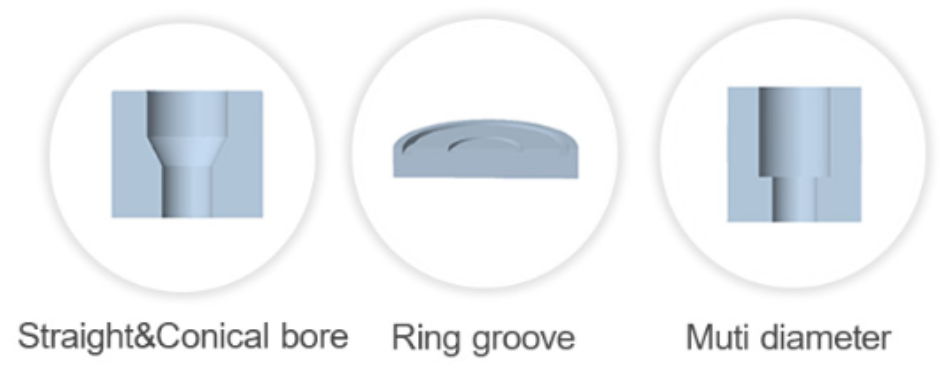

1 | Welding workpiece type | Round tube, plane circle, elevation circular channel, elevation concentric reducing channel, ball valve ball intersection line, steel ring groove. |

2 | Welding materials | Stainless steel, nickel base, copper alloy, etc. Wire diameter: 1.0-1.2mm |

3 | Welding thickness and speed | Single-layer welding thickness :1.0-2.5mm Welding speed :100-300mm/min |

4 | Welding position | 1G\2G position |

5 | Range of weldable workpieces | Minimum post-weld inner diameter 40 mm Maximum surfacing inner diameter 1200mm |

6 | Equipment function | Arc height tracking (AVC), welding parameter storage and call welding time record, system safety and alarm,remote monitoring function. |

APPLICATIONS

Fields marked with an * are required

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.